As part of her America at Work tour, Secretary Lori Chavez-DeRemer is visiting companies with apprenticeship programs and training centers around the country to see firsthand how they are preparing workers for the in-demand, high-skilled jobs of the future. Skilled tradespeople are crucial to fulfilling the Administration’s mission to revitalize the American Workforce – and Registered Apprenticeship is a critical pathway to these good jobs. Did you know that apprenticeship grads have an average starting salary of over $80,000?

In fact, Registered Apprenticeship has been an important – but underused – way to earn and learn for years. It’s also how my father’s 34-year career manufacturing Navy vessels began. If you’re considering a new job, here are four reasons he shared for choosing an apprenticeship.

1. Earn money while learning on the job

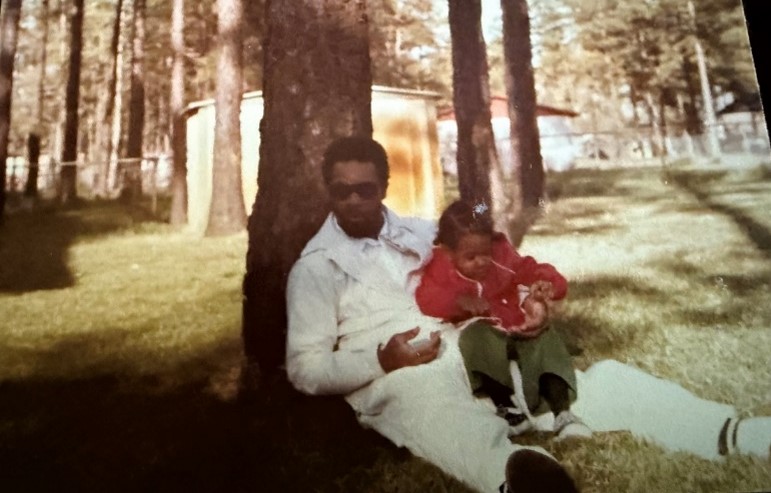

On a hot summer day in 1973, my father decided to walk into Norfolk Naval Shipyard and start his career as a sheet metal apprentice. He chose the apprenticeship program based on the opportunity to learn a trade while earning a decent living to support his family. There were eight apprentices in the sheet metal shop — five men and three women.

2. Gain industry-standard certifications

The program at that time consisted of working in the shipyard for nine months followed by three months of studying the trade at the local community college. Fast forward half a century: The Norfolk Naval Shipyard Apprentice Program is still attracting talent, and the partnership with Tidewater Community College (TCC) is still successful. I asked my father which course was the most challenging. He recalled that the entire curriculum was rigorous, but the “Statics: Strengths of Materials” course was the most difficult for him. That course trained apprentices on the principles and methods of structural mechanics to include topics like static equilibrium, force resultants, stress-strain relationships and Hooke’s Law.

3. Participate in practical learning

One story my father likes to tell is an experience from his first day at work. After the onboarding process was complete, the instructor took the apprentices onto a ship so that they could see firsthand what mechanics do on the job. He stepped off the gangway, onto the ship’s deck plate and was immediately startled by the loud noise of a chipping hammer, a tool similar to a jack hammer but used on ships. From Day One, he had the experience of working in a real-world industrial environment.

4. Elevate career advancement

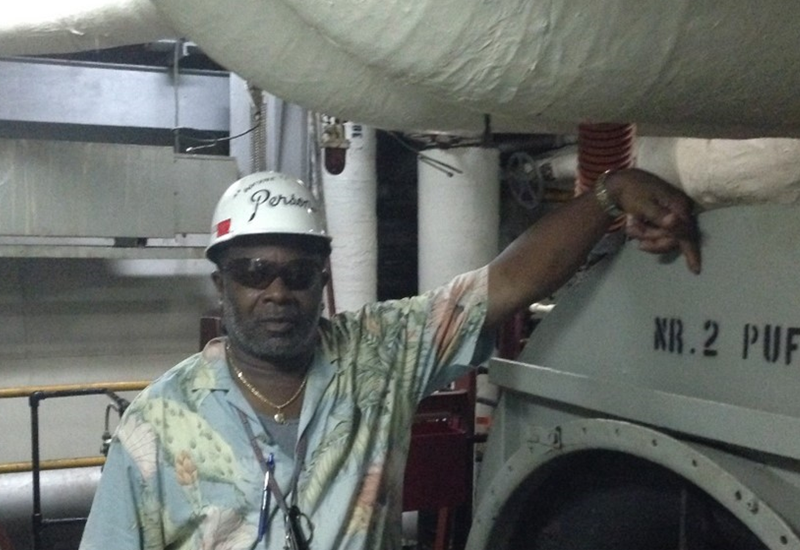

After 34 years of service, my father was used to the sound of the chipping hammer and become familiar and accustomed to all the other tools that were used in ship construction and repair. The apprenticeship program laid a path that allowed him to tap into limitless possibilities for career advancement. He moved up through the ranks and was promoted from apprentice, to instructor, planner and supervisor, and concluded his career as a production controller who ensured Navy vessels were repaired properly. All of those promotions were the result of hard work, determination and a pathway created by an apprenticeship program.

As the Labor-Management Partnership Coordinator for the Department of Labor, I’m passionate about apprenticeship programs because they provide a path for workers to gain practical experience while also ensuring employers have a qualified workforce. In essence, apprenticeship programs act as a kind of bridge, serving workers while helping employers strengthen and expand their operations, which is key to the Administration’s goal of increasing manufacturing jobs.

That same bridge extends into the scope of how labor-management partnerships are built and sustained, which is good news for American workers, families and businesses. Just like the slogan for Tidewater Community College states, “From here, go anywhere.”

Editor’s note: The Department of Labor is here to help connect more Americans to these good-paying jobs. Job seekers and employers can learn more at apprenticeship.gov. Interested in starting or growing a labor-management partnership program? Visit dol.gov/LMPP.

Darnice Marsh is the labor-management partnership coordinator in the Department of Labor’s Office of Labor-Management Standards.

U.S. Department of Labor Blog

U.S. Department of Labor Blog